Introduction

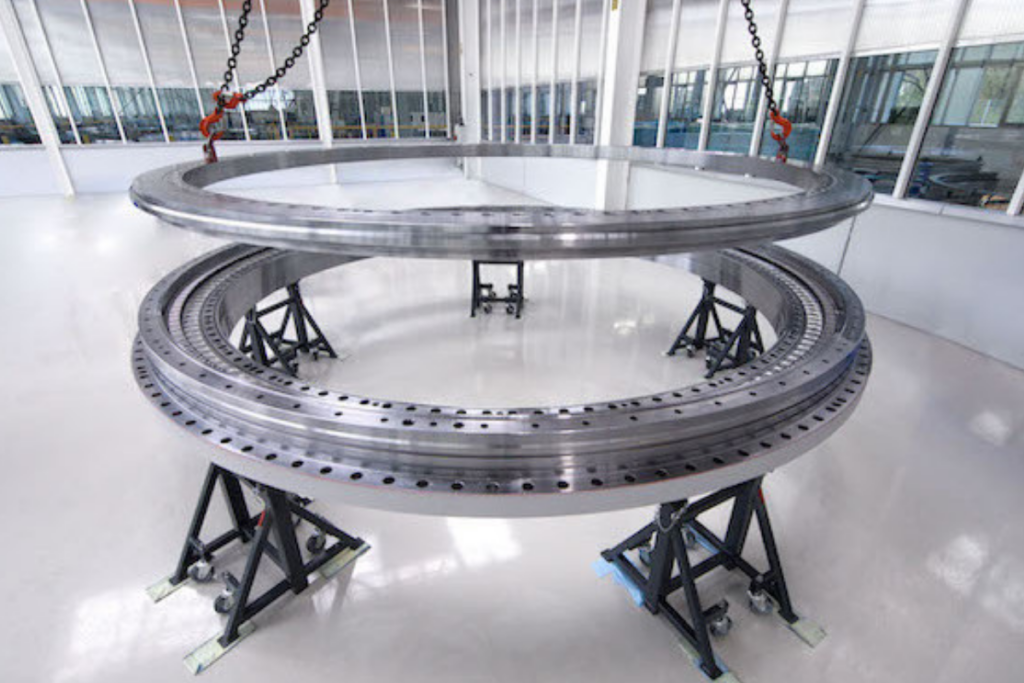

Slewing bearings, also known as turntable bearings or slewing rings, are crucial components in various industries, facilitating the smooth rotation of heavy machinery and equipment. As businesses strive for efficiency and productivity, the demand for high-quality slewing bearings continues to rise. In this article, we delve into the realm of slewing bearing manufacturers, exploring the top players in the industry and their contributions to the market.

Top 18 Slewing Bearing Manufacturers in 2024

In 2024, the slewing bearing market is dominated by a select group of manufacturers renowned for their exceptional products and industry leadership. These companies have earned their positions through years of dedication to excellence and a commitment to meeting the evolving needs of their customers. Let’s explore the top 18 slewing bearing manufacturers leading the market in 2024 and understand what sets them apart.

Leading Slewing Bearing Manufacturers

Introduction:

THK Co., Ltd. is a renowned company in the mechanical engineering domain, specializing in the production of high-quality Slewing Bearings. This article highlights the advantages and applications of THK’s Slewing Bearings, emphasizing their significance in various mechanical systems.

Advantages of THK’s Slewing Bearings:

THK’s Slewing Bearings offer several advantages that make them indispensable components in mechanical systems. Firstly, these bearings are engineered with precision and accuracy, ensuring smooth and efficient rotation with minimal friction. Secondly, THK’s Slewing Bearings are known for their robust construction and durability, capable of withstanding heavy loads and harsh operating conditions without compromising performance. THK is the famous slewing bearing manufacturer. Additionally, these bearings feature advanced sealing mechanisms that enhance their reliability and longevity, making them suitable for long-term use in critical applications.

Applications of THK’s Slewing Bearings:

THK’s Slewing Bearings find extensive use across diverse applications in the mechanical engineering sector. In the industrial machinery domain, these bearings are utilized in rotating platforms, turntables, and indexing systems, facilitating precise positioning and smooth motion control. Moreover, THK’s Slewing Bearings are also employed in construction equipment such as cranes and excavators, enabling stable rotation and lifting operations. Furthermore, these bearings play a crucial role in the aerospace industry, where they are integrated into aircraft landing gear systems to support heavy loads during takeoff and landing maneuvers.

2.NMB Technologies Corporation

Introduction

NMB Technologies Corporation is a prominent player in sthe mechanical engineering sector, specializing in the design and manufacturing of high-quality bearings, with a particular focus on Slewing Bearings. This article delves into the classification of bearings and discusses the advantages and disadvantages of Slewing Bearings offered by NMB Technologies Corporation.

Bearing Classification

NMB Technologies Corporation produces a wide range of bearings classified based on their design and application. Common classifications include ball bearings, roller bearings, and plain bearings. Ball bearings utilize balls to maintain separation between the bearing races, offering low friction and high efficiency. Roller bearings, on the other hand, use cylindrical rollers to support radial and axial loads, providing enhanced load-carrying capacity. Plain bearings, also known as bushings, feature sliding surfaces to facilitate rotational or linear movement with minimal friction. s

Advantages and Disadvantages of NMB Slewing Bearings

NMB Technologies Corporation’s Slewing Bearings offer several advantages suitable for various mechanical applications. These bearings are renowned for their robust construction, capable of withstanding heavy loads and harsh operating conditions. Additionally, NMB Slewing Bearings exhibit high precision and accuracy, ensuring smooth rotational movement and precise positioning. However, one potential drawback of Slewing Bearings is their relatively complex installation and maintenance requirements, which may increase operational costs and downtime.

3.Xuzhou wanda slewing bearing co.ltd

Introduction

Xuzhou Wanda Slewing Bearing Co. Ltd. is a renowned manufacturer in the mechanical industry, specializing in the production of high-quality slewing bearings. With years of experience and expertise, Xuzhou Wanda has established itself as a leading supplier of slewing bearings globally.

Types of Bearings Manufactured by Xuzhou Wanda:

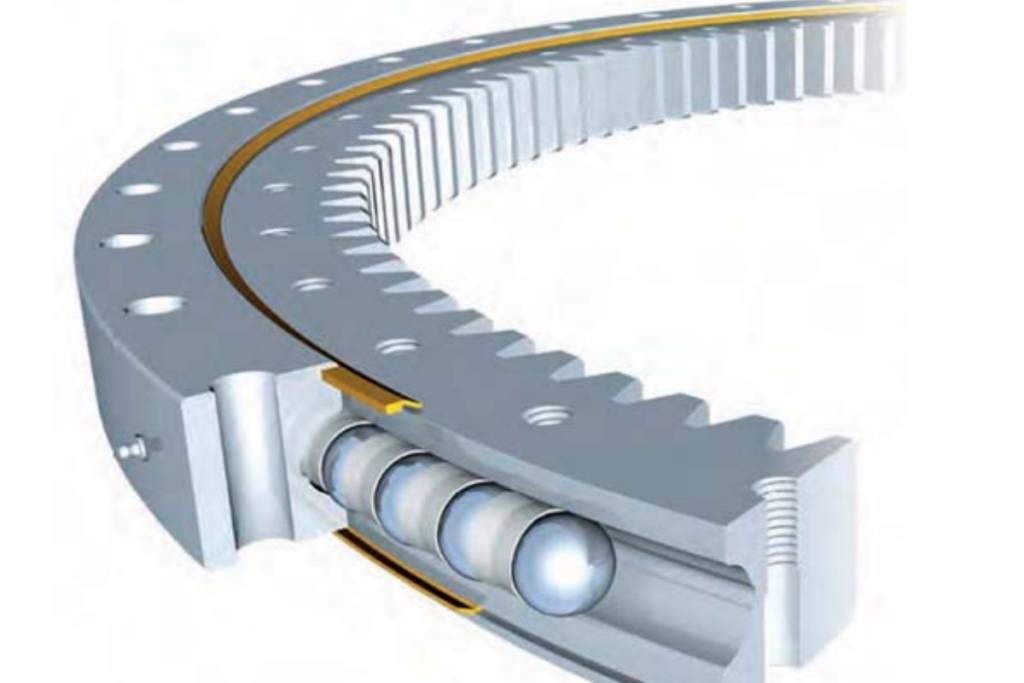

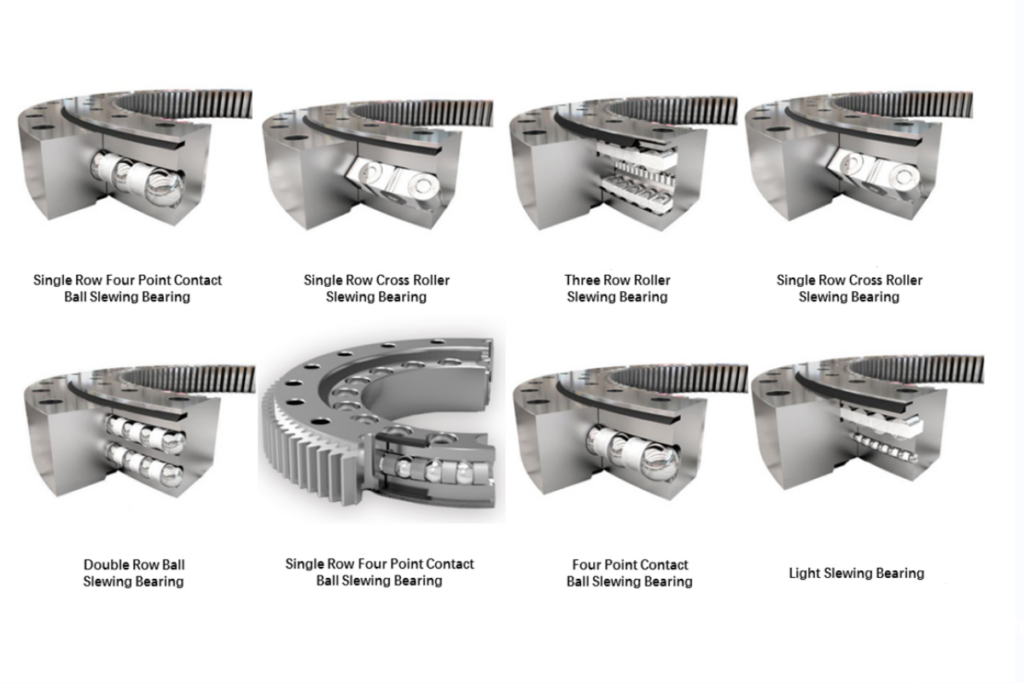

– Single-row Slewing Bearings: These bearings consist of a single row of balls or rollers, providing excellent load-carrying capacity and rotational precision.

– Double-row Slewing Bearings: Designed with two rows of rolling elements, double-row slewing bearings offer increased load capacity and enhanced stability.

– Cross Roller Slewing Bearings: Featuring crossed cylindrical rollers, cross roller slewing bearings are ideal for applications requiring high rigidity and precision.

Advantages of Xuzhou Wanda Slewing Bearings:

1. High Load Capacity: Xuzhou Wanda slewing bearings are engineered to withstand heavy loads, making them suitable for a wide range of applications, including cranes, excavators, and wind turbines.

2. Precision Engineering: With advanced manufacturing techniques and stringent quality control measures, Xuzhou Wanda ensures that its slewing bearings meet the highest standards of accuracy and reliability.

3. Durability: Xuzhou Wanda slewing bearings are constructed from premium-quality materials, ensuring long-term durability and minimal maintenance requirements.

4. Customization Options: Xuzhou Wanda offers customizable slewing bearing solutions to meet the unique needs of each application, providing flexibility and versatility to customers.

4.Kaydon bearings

Introduction

Kaydon Bearings is a leading manufacturer of precision-engineered bearings, serving various industries, including aerospace and transportation systems. Renowned for their innovative designs and superior quality, Kaydon Bearings has established itself as a trusted provider in the market.

Key Products Offered by Kaydon Bearings

Kaydon Bearings offers a wide range of products tailored to meet the diverse needs of the aerospace and transportation sectors, including:

– Slewing Bearings: Designed to support axial, radial, and moment loads simultaneously, Slewing Bearings by Kaydon are crucial components in various applications, including cranes, excavators, and aerospace equipment.

Installation Guide for Slewing Bearings by Kaydon

Proper installation of Slewing Bearings is essential to ensure optimal performance and longevity. Here are some key steps to follow:

1. Pre-Installation Inspection: Thoroughly inspect the Slewing Bearing and its components for any signs of damage or defects before installation.

2. Mounting Surface Preparation: Ensure that the mounting surface is clean, flat, and free of any debris or contaminants that could affect the bearing’s performance.

3. Alignment: Proper alignment of the Slewing Bearing is crucial to prevent premature wear and ensure smooth operation. Use precision alignment tools to achieve the desired alignment.

4. Lubrication: Apply the recommended lubricant to the bearing’s raceway surfaces and mating surfaces to reduce friction and extend service life.

5. Torque Specifications: Follow the manufacturer’s recommendations for tightening torque to prevent overloading or damaging the bearing during installation.

Introduction:

MinebeaMitsumi Inc. is a key player in the mechanical engineering sector, renowned for its innovative solutions and cutting-edge products. This article delves into MinebeaMitsumi’s primary offerings, focusing on its renowned Slewing Bearings and their distinctive features.

Main Products:

MinebeaMitsumi Inc. boasts a comprehensive range of products catering to diverse mechanical engineering needs. From precision components and bearings to motors and sensors, the company’s portfolio encompasses a wide array of solutions designed to enhance performance and reliability across various applications. Among its flagship products, Slewing Bearings occupy a prominent position, serving as essential components in machinery and equipment requiring rotational movement.

Slewing Bearings:

At the heart of MinebeaMitsumi’s product lineup are its Slewing Bearings, which excel in providing smooth and precise rotational motion in a variety of applications. These bearings are characterized by their robust construction, high load-bearing capacity, and exceptional durability. Whether used in cranes, excavators, wind turbines, or solar trackers, MinebeaMitsumi’s Slewing Bearings offer unparalleled performance and reliability, ensuring seamless operation even in demanding environments.

Distinctive Features:

MinebeaMitsumi’s Slewing Bearings stand out for their advanced design and engineering, incorporating features such as raceway profiles optimized for load distribution, sealed construction for enhanced durability, and precision machining for tight tolerances. Moreover, the company offers custom solutions tailored to specific customer requirements, demonstrating its commitment to delivering optimal performance and value.

Introduction:

In the realm of mechanical engineering, the SKF Group stands as a formidable entity, renowned for its exceptional contributions and innovative solutions. This article delves into the key aspects of SKF’s operations, focusing on its primary products and the advantages of its Slewing Bearings.

Main Products:

SKF Group boasts an extensive range of products catering to various mechanical applications. Among its main offerings are bearings, seals, lubrication systems, and related services. However, one of its standout products is the Slewing Bearing, which plays a crucial role in facilitating smooth rotational movement in heavy machinery and equipment.

Advantages of SKF Slewing Bearings:

SKF’s Slewing Bearings offer numerous advantages that set them apart in the market. Firstly, they are engineered to withstand high axial and radial loads, ensuring optimal performance even in demanding environments. Additionally, SKF Slewing Bearings are known for their durability and longevity, contributing to enhanced reliability and reduced maintenance costs for industrial machinery. Furthermore, SKF’s commitment to innovation ensures that its Slewing Bearings incorporate the latest advancements in technology, resulting in improved efficiency and productivity for end-users.

Introduction:

Nachi-Fujikoshi Corp. is a prominent name in the field of mechanical engineering, renowned for its extensive range of products designed to meet the diverse needs of industries worldwide. This article explores the company’s main offerings, focusing on its acclaimed Slewing Bearings and their distinctive characteristics.

Main Products:

Nachi-Fujikoshi Corp. boasts a comprehensive portfolio of products catering to various sectors within the mechanical engineering domain. From bearings and hydraulic equipment to robotics and automotive components, the company’s lineup encompasses a wide array of solutions aimed at enhancing efficiency and performance across different applications. Central to its product range are Slewing Bearings, which play a crucial role in facilitating rotational movement in machinery and equipment.

At the core of Nachi-Fujikoshi’s product lineup are its Slewing Bearings, which are engineered to deliver exceptional performance and reliability in demanding environments. These bearings feature a compact design, high load-bearing capacity, and smooth rotational movement, making them ideal for applications requiring precise positioning and smooth operation. Whether used in construction equipment, industrial machinery, or renewable energy systems, Nachi-Fujikoshi’s Slewing Bearings excel in delivering optimal performance.

Distinctive Features:

Nachi-Fujikoshi’s Slewing Bearings stand out for their advanced design and innovative features, including precision machining, high-quality materials, and advanced sealing technologies. These bearings are known for their durability, longevity, and resistance to harsh operating conditions, ensuring uninterrupted performance even in challenging environments. Moreover, Nachi-Fujikoshi offers customized solutions tailored to specific customer requirements, further enhancing the versatility and applicability of its Slewing Bearings.

Introduction:

RBC Bearings Inc. is a prominent player in the mechanical engineering sector, renowned for its expertise in producing high-quality bearings that serve a wide range of industrial applications. This article delves into the advantages and applications of RBC Bearings’ Slewing Bearings, highlighting their significance in various mechanical systems.

Advantages of RBC Bearings’ Slewing Bearings:

RBC Bearings’ Slewing Bearings offer several advantages that make them indispensable components in mechanical systems. Firstly, these bearings are known for their exceptional load-carrying capacity, allowing them to support heavy loads while maintaining smooth and efficient rotational movement. Additionally, RBC Bearings’ Slewing Bearings exhibit high precision and accuracy, ensuring precise positioning and alignment in critical applications. Furthermore, these bearings are designed for durability and reliability, with robust construction and advanced sealing mechanisms that enhance their performance and longevity even in harsh operating conditions.

Applications of RBC Bearings’ Slewing Bearings:

RBC Bearings’ Slewing Bearings find widespread use across various industries and applications due to their versatility and reliability. In the aerospace sector, these bearings are employed in aircraft landing gear systems, providing smooth rotation and precise positioning during takeoff and landing operations. In the construction industry, RBC Bearings’ Slewing Bearings are utilized in heavy-duty equipment such as cranes and excavators, facilitating the rotation of booms and lifting arms with precision and stability. Moreover, these bearings are also utilized in renewable energy systems such as wind turbines, where they enable efficient rotation of turbine blades to harness wind energy.

Introduction:

In the realm of mechanical engineering, the Timken Company stands out as a leading provider of bearings and related products. This article explores the importance of bearing maintenance in the mechanical industry, with a specific focus on Timken’s contributions in this regard, including its Slewing Bearings and their advantages.

Bearing Maintenance:

Proper maintenance of bearings is essential to ensure their longevity and optimal performance. Timken Company offers comprehensive guidance on bearing maintenance, including regular inspections, lubrication, and replacement of worn components. By following Timken’s recommended maintenance procedures, industries can mitigate the risk of premature bearing failure and minimize downtime in their operations.

Slewing Bearings and Their Advantages:

Slewing Bearings from the Timken Company offer several advantages in mechanical applications. These bearings are designed to withstand heavy radial and axial loads while facilitating smooth rotational movement. They are highly durable, resistant to corrosion, and require minimal maintenance. Additionally, Timken’s Slewing Bearings are known for their precision engineering, ensuring precise positioning and alignment in various industrial settings.

10.NSK Ltd.

Introduction:

In the realm of mining equipment, NSK Ltd. holds a significant position as a provider of high-quality bearings. This article delves into the various product categories offered by NSK Ltd. in the mining equipment sector, with a particular focus on their Slewing Bearings.

Among NSK Ltd.’s offerings, Slewing Bearings stand out as essential components in mining equipment. These bearings are designed to withstand heavy radial and axial loads while facilitating smooth rotational movement. NSK’s Slewing Bearings are engineered with precision to meet the rigorous demands of the mining industry, offering reliability and durability even in harsh operating conditions.

Product Classification:

NSK Ltd. offers a diverse range of bearings tailored to meet the specific needs of the mining equipment industry. Their product lineup includes various types of bearings such as ball bearings, roller bearings, and specialized Slewing Bearings. These bearings play a crucial role in supporting heavy loads and ensuring smooth operation in mining machinery, contributing to enhanced efficiency and productivity.

11.Luoyang LYC Bearing Co., Ltd.

Introduction:

Luoyang LYC Bearing Co., Ltd. is a leading manufacturer in the field of mechanical engineering, specializing in the production of high-quality bearings tailored for aerospace and transportation systems. This article explores the advantages and structural features of Luoyang LYC’s Slewing Bearings, highlighting their significance in aerospace and transportation applications.

Advantages of Luoyang LYC’s Slewing Bearings:

Luoyang LYC’s Slewing Bearings offer several advantages crucial for aerospace and transportation systems. Firstly, these bearings are known for their exceptional load-carrying capacity, enabling them to support heavy loads while maintaining smooth and precise rotational movement. Additionally, Luoyang LYC’s Slewing Bearings exhibit high precision and accuracy, ensuring reliable performance and precise positioning in critical aerospace and transportation applications. Moreover, these bearings feature compact designs and lightweight structures, contributing to overall system efficiency and minimizing energy consumption.

Structural Features of Luoyang LYC’s Slewing Bearings:

Luoyang LYC’s Slewing Bearings are characterized by their advanced structural design, optimized for aerospace and transportation systems. These bearings typically feature raceway surfaces that are hardened and ground to precision tolerances, ensuring smooth operation and extended service life. Furthermore, Luoyang LYC’s Slewing Bearings incorporate advanced sealing and lubrication systems, providing effective protection against contaminants and ensuring reliable performance in harsh operating environments. Additionally, these bearings are often equipped with integrated mounting features, facilitating easy installation and maintenance in aerospace and transportation systems.

12.Triangle Manufacturing Company

Introduction

Triangle Manufacturing Company is a prominent player in the aerospace and transportation systems industry, specializing in the production of high-quality Slewing Bearings. With a reputation for reliability and innovation, Triangle Manufacturing Company has become a trusted supplier for various critical applications in these sectors.

Triangle Manufacturing Company offers a comprehensive range of bearings, including:

– Ball Bearings: Ideal for applications requiring high-speed rotation and minimal friction.

– Roller Bearings: Suitable for heavy-duty applications and capable of handling radial an sd axial loads.

– Thrust Bearings: Designed to withstand axial loads in one direction and often used in combination with other bearings.

– Slewing Bearings: Specifically engineered for applications requiring smooth rotation and support of heavy loads in various directions.

The bearings produced by Triangle Manufacturing Company boast several structural features, including:

– High-quality materials: Utilization of premium materials such as stainless steel and advanced alloys ensures durability and longevity.

– Precision engineering: Each bearing is meticulously designed and manufactured to exacting standards, resulting in superior performance and reliability.

– Sealing and lubrication systems: Incorporation of advanced sealing and lubrication mechanisms minimizes friction, reduces wear, and extends service life.

– Modular design: Many bearings feature a modular design, allowing for easy maintenance, repair, and replacement of individual components.

Introduction:

In the realm of mechanical engineering, the Schaeffler Group stands as a prominent entity known for its innovative solutions and extensive product range. This article delves into the key aspects of the Schaeffler Group’s operations, focusing on its primary products and providing guidance on the installation of Slewing Bearings.

Main Products:

The Schaeffler Group offers a comprehensive array of products catering to various mechanical applications. Among its main offerings are bearings, linear technology, and automotive components. However, one of its standout products is the Slewing Bearing, which plays a crucial role in facilitating smooth rotational movement in heavy machinery and equipment.

Installation Guidance for Slewing Bearings:

When installing Slewing Bearings from the Schaeffler Group, it is essential to follow precise guidelines to ensure optimal performance and longevity. Begin by carefully inspecting the bearing and surrounding components for any damage or defects. Next, clean the mounting surfaces thoroughly and apply lubrication as recommended by the manufacturer. Then, accurately align the bearing and secure it in place using appropriate fasteners. Finally, conduct thorough testing to verify the functionality and alignment of the Slewing Bearing before putting it into operation.

Introduction

Koyo Bearings is a leading name in the industrial sector, renowned for its innovative solutions and high-quality products. This article explores the advantages and structural characteristics of Koyo’s Slewing Bearings, highlighting their significance in industrial applications.

Advantages of Koyo Slewing Bearings

Koyo Slewing Bearings offer several advantages that make them indispensable in various industrial settings. One notable advantage is their exceptional load-carrying capacity, enabling them to withstand heavy radial and axial loads with ease. Additionally, these bearings exhibit high precision and accuracy, ensuring smooth rotational movement and precise positioning, crucial for critical industrial operations. Moreover, Koyo Slewing Bearings are known for their durability and reliability, providing long-lasting performance even in challenging environments.

Structural Characteristics

Koyo Slewing Bearings boast a robust construction designed to withstand rigorous industrial demands. They typically feature an integrated raceway design, which optimizes load distribution and enhances bearing performance. Furthermore, Koyo employs advanced materials and manufacturing techniques to ensure the integrity and longevity of their Slewing Bearings. These bearings often incorporate sealed or shielded designs to prevent contamination and retain lubrication, prolonging their service life in harsh industrial environments.

Introduction

Nippon Thompson Co., Ltd. is a leading provider of Slewing Bearings in the aviation and transportation industry. These bearings play a vital role in various applications within the sector, offering different types with unique advantages and disadvantages.

Types of Slewing Bearings Offered by Nippon Thompson Co., Ltd.

| Type | Advantages | Disadvantages |

| Single-row | 1. Simple design | 1. Limited load-carrying capacity |

| 2. Compact and lightweight | 2. Susceptible to misalignment | |

| 3. Cost-effective | ||

| Double-row | 1. Higher load capacity | 1. Increased size and weight |

| 2. Improved stability | 2. Higher cost | |

| 3. Enhanced stiffness | ||

| Crossed roller | 1. High rotational accuracy | 1. Limited axial load capacity |

| 2. Reduced friction | 2. Higher cost | |

| 3. Compact design |

16.C&U Group

Introduction

C&U Group is a renowned name in the aviation and transportation industry, providing a wide range of high-quality Slewing Bearings. These bearings are crucial components in various applications within the sector, ensuring smooth operations and reliability.

Types of Slewing Bearings Offered by C&U Group

C&U Group offers a variety of Slewing Bearings, each designed to meet specific requirements:

- Single-row Slewing Bearings: Known for their simple design and cost-effectiveness.

- Double-row Slewing Bearings: Designed for higher load capacity and stability.

- Crossed roller Slewing Bearings: Known for high rotational accuracy and reduced friction.

Maintenance and Repair of Slewing Bearings by C&U Group

C&U Group provides comprehensive maintenance and repair services for their Slewing Bearings, ensuring their longevity and optimal performance. This includes regular inspections, lubrication, and replacement of worn-out parts.

Introduction

ILJIN Bearing Co., Ltd. is a leading manufacturer in the aviation and transportation industry, specializing in the production of high-quality Slewing Bearings. These bearings are crucial components in various applications within the sector, ensuring smooth operations and reliability.

Types of Slewing Bearings Offered by ILJIN Bearing Co., Ltd.

ILJIN Bearing Co., Ltd. offers a diverse range of Slewing Bearings, tailored to meet specific requirements:

- Single-row Slewing Bearings: Simple in design and suitable for light to moderate loads.

- Double-row Slewing Bearings: Designed for higher load capacities and increased stability.

- Crossed roller Slewing Bearings: Known for their high rotational accuracy and ability to handle heavy loads.

Maintenance and Repair of Slewing Bearings by ILJIN Bearing Co., Ltd.

ILJIN Bearing Co., Ltd. provides comprehensive maintenance and repair services for their Slewing Bearings, ensuring their longevity and optimal performance. This includes regular inspections, lubrication, and replacement of worn-out components, contributing to extended service life and reduced downtime.

Introduction:

In the realm of mechanical engineering, NTN Corporation emerges as a key player, offering a diverse array of products to meet industry demands. This article delves into NTN Corporation’s main product offerings, particularly focusing on Slewing Bearings and their notable advantages in various applications.

Main Products:

NTN Corporation, a renowned name in the mechanical engineering sector, boasts a wide range of products catering to different industries. Among its primary offerings are bearings, precision machinery, and automotive components. NTN’s bearings encompass various types, including ball bearings, roller bearings, and Slewing Bearings, each designed to deliver optimal performance and reliability in demanding applications.

NTN Corporation’s Slewing Bearings stand out as exceptional components designed to facilitate smooth rotation and movement in heavy machinery and equipment. These bearings are engineered to withstand high axial and radial loads, making them ideal for use in cranes, excavators, wind turbines, and other industrial applications. With their robust construction and precise engineering, NTN’s Slewing Bearings ensure minimal downtime, increased operational efficiency, and enhanced safety in critical operations.

Advantages:

The advantages of NTN Corporation’s Slewing Bearings are manifold. Their superior load-bearing capacity and precise design result in reduced friction, minimizing wear and extending the lifespan of machinery. Additionally, NTN’s Slewing Bearings offer exceptional accuracy and stability, enabling precise positioning and control in various applications. Furthermore, their compact design and lightweight construction contribute to ease of installation and maintenance, further enhancing their appeal to industries seeking reliable and efficient solutions.

Market Analysis and Trends

The slewing bearing market is witnessing several notable trends in 2024, including advancements in materials and manufacturing processes, stricter industry regulations, and the emergence of new applications. Despite facing challenges such as fluctuating raw material costs and geopolitical uncertainties, slewing bearing manufacturers are capitalizing on opportunities in sectors like renewable energy and industrial automation.

Future Outlook

Looking ahead, the future of the slewing bearing market appears promising, with continued growth expected driven by factors such as urbanization, infrastructure development, and technological innovation. Top manufacturers are poised to lead this growth trajectory by investing in research and development, expanding their product portfolios, and strengthening their global presence.

Conclusion

In conclusion, the top 18 slewing bearing manufacturers leading the market in 2024 represent the pinnacle of excellence and innovation in the industry. Their relentless pursuit of quality, customer satisfaction, and market adaptability ensures that they remain at the forefront of an ever-evolving market landscape. As businesses navigate the complexities of selecting slewing bearing suppliers, these manufacturers stand ready to provide reliable solutions and support for their diverse needs.